Naval & Patrol Vessels

- Naval vessels

- Patrol vessels

- Coastguard vessels

- Mine countermeasure vessels

- Frigates

- Offshore patrol vessels

- Harbour patrol vessels

- Survey vessels

- Landing platforms/docks (LPDs)

- Corvettes

- Landing crafts

- Interceptor Craft

- Police boats

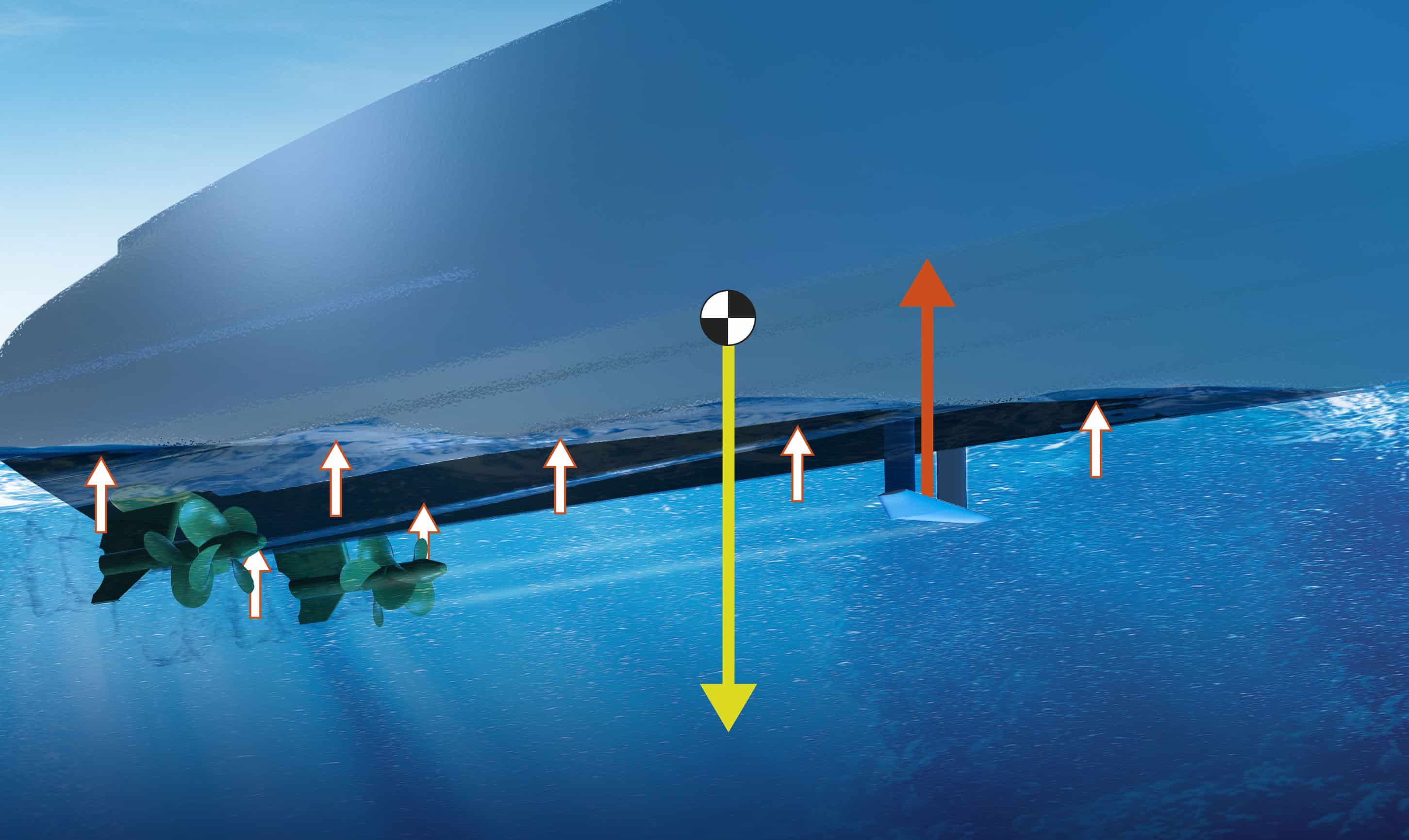

Benefits Hull Vane®

Speed

- Higher speed thanks to reduced resistance.

- Improved sailing characteristics.

Range

- Same range at higher speed.

- Extended range.

Seakeeping

- Reduced motion in waves produces a stable platform for crew to execute their mission.

- Safer launch & recovery of daughter craft or USV’s.

- Safer helicopter/drone landings.

- Improved working conditions for crew.

Noise

- Reduced exterior noise levels thanks to reduced stern wave.

- Reduced interior noise levels due to lower propeller and engine loads.

- Lower propeller and engine sound radiation.

Wash & Wake

- Reduced stern wave makes vessel less traceable by airborne vehicles.

- Reduced vessel wake also makes vessel less vulnerable to wake-homing torpedoes

Foil Assist benefits

- Improved sailing comfort and safety.

- Reduced pitching and slamming.

- Improved sailing behaviour.

- Less spray for a drier ride.

- Higher speed when sailing through waves

- Reduced seasickness.

Financing Possibilities with Hull Vane®!

Hull Vane offers financing possibilities and benefits across a range of options. As a strategic maritime partner dedicated to collaborative success, we ensure a straightforward process for acquiring our high-quality solutions.

By choosing one of the financing possibilities, you ensure peace of mind and increased profitability. Sail into success with confidence and let profit margins do the talking with Hull Vane as your partner for the future.

Read more about our financing offers here.

Portfolio

Shipyards