Commercial ships

- Expedition cruise vessels

- Passenger ships & ferries

- Offshore vessels

- Workboats

- Coasters (<200m)

- Ro-ro ships

- Research vessels

- Fast supply vessels

- Crewboats

- Container vessels

- Fast transfer boats

- Windfarm service vessels

- Daughter craft

- Watertaxis

- Passenger RHIBs

- Aquaculture support boats

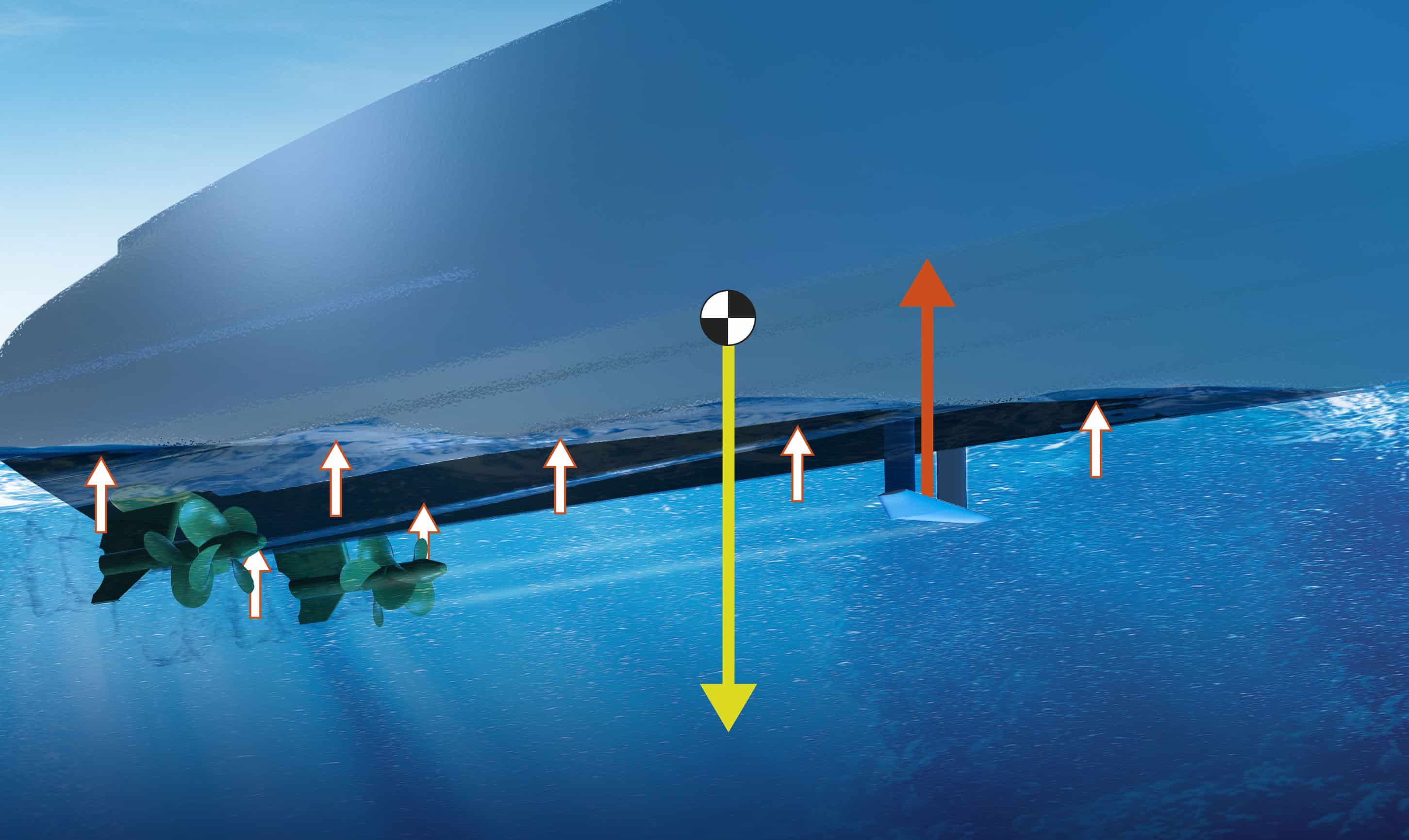

Benefits Hull Vane®

Maximum operability

- Reduced motions in waves means a stable platform for the crew to execute their mission.

- Reduced seasickness of passengers enhance the experience on board

Reduced fuel costs

- Lower operational expenditure (OPEX) due to reduced fuel consumption (5–25%)

- Applies to conventional fuels as well as alternative sources of energy, such as batteries, methanol, hydrogen, etc.

- Greater range (or same range at a higher speed), due to reduced fuel consumption.

Future ready

- Reduced CO2, NOx and SOx emissions thanks to improved fuel consumption.

- Fewer batteries needed to produce the same range and top speed on board electric vessels.

- Conversion to other fuel is made easier due to less vessel resistance.

- Less capacity for hydrogen needed.

- Conversion to methanol is easier without increasing fuel capacity.

Foil Assist benefits

- Improved sailing comfort and safety.

- Reduced pitching and slamming.

- Improved sailing behaviour.

- Less spray for a drier ride.

- Higher speed when sailing through waves

- Reduced seasickness.

Financing Possibilities with Hull Vane®!

Hull Vane offers financing possibilities and benefits across a range of options. As a strategic maritime partner dedicated to collaborative success, we ensure a straightforward process for acquiring our high-quality solutions.

By choosing one of the financing possibilities, you ensure peace of mind and increased profitability. Sail into success with confidence and let profit margins do the talking with Hull Vane as your partner for the future.

Read more about our financing offers here.

Portfolio

Shipyards